Here it is 2025 and almost the end of January and I haven’t posted in a while. I’m going to try and post directly to WordPress instead of using Word then transferring the file. I liked using Word when there was a template to use but the new version seems to have dropped that capability.

Here it is 2025 and almost the end of January and I haven’t posted in a while. I’m going to try and post directly to WordPress instead of using Word then transferring the file. I liked using Word when there was a template to use but the new version seems to have dropped that capability.

OK…I posted a picture…that’s good. In case you’re wondering what’s in the picture, it is a face made out of stuff I find on my morning walks. Today, the face was very different. It was painted brown. The tree where the face exists sits next to a bench. Apparently, those that maintain the walking/biking trail stained the bench and used a bit to add a little color to the face.

The face is on  my “turn around” tree which is 2 miles from home. Every day, except Friday, I walk to the turn around tree and head back for a 4-mile walk. Hopefully, this exercise will allow me to live longer.

my “turn around” tree which is 2 miles from home. Every day, except Friday, I walk to the turn around tree and head back for a 4-mile walk. Hopefully, this exercise will allow me to live longer.

I love living in Tucson. The temperature at 9 this morning was a bit over 50 degrees (F). I light jacket was all that was required. On the way home I saw a pretty bird in a tree. I don’t know birds, but he looked a little like a bandit.

a pretty bird in a tree. I don’t know birds, but he looked a little like a bandit.

When I’m walking, I pick up litter using a Harbor Freight Pickup Tool. I carry shopping bags from our local Safeway store. Also, I carry soft beef flavored treats for the four-footed friends I see along the way. I know their names, but I rarely know the names of the people walking them. I listen to podcasts, too. I have a set of “open ear” headphones that transfer sound through bones. I listen to NPR News (as depressing as it has been lately), and SCIFRI (which isn’t only on Fridays now). I also listen to other NPR podcasts such as: NPR Politics, Consider This, and The Best of Car Talk, and many others including: 99% Invisible, Cabinet of Curiosities, Al Franken, Apple News, Big Picture Science, BrainStuff, Cautionary Tales, Cognitive Dissonance, The Constant, Creature Feature, Criminal, The Daily, Freakonomics, Freethought Radio, … I’d better stop now. the list goes on and I’m down to the Fs.

That’s a lot of podcasts. I have to listen to them at at least 1.5X speed to get through them. I also have a couple of mainly music podcasts such as Vinyl on Chrome. Those, I have to listen to at 1X, of course.

So, I’m walking, picking up trash, decorating the path, listening to podcasts, and feeding dogs. I’m also thinking about what I’m going to write in my blog. I always think about it but by the time I’m home, eat my lunch, and bathe, I usually forget about the blog and fix something, or finish a project, or watch YouTube videos.

Today, I decided to write a blog just before bed…good night all.

Winter Solstice is right around the corner. In fact, it is one week from today on a Sunday this year. What that means is that I can have the annual winter solstice celebration start a bit earlier. I can light the celebratory fire a little closer to the actual sundown. The solar lights I planted in the ground last year didn’t survive. I needed to replace them all and there are 40 of them. This year, I’m putting in some waterproof light pucks although; I won’t bury them so that they’re at ground level this year. I’ll put them on the ground protected by some 3D printed PETG cups. Did I mention that there were 40 of them? For a maker, doing a thing once is kinda fun. Doing something 40 times becomes work! However, putting in the extra effort and doing something right usually works out in the end.

Winter Solstice is right around the corner. In fact, it is one week from today on a Sunday this year. What that means is that I can have the annual winter solstice celebration start a bit earlier. I can light the celebratory fire a little closer to the actual sundown. The solar lights I planted in the ground last year didn’t survive. I needed to replace them all and there are 40 of them. This year, I’m putting in some waterproof light pucks although; I won’t bury them so that they’re at ground level this year. I’ll put them on the ground protected by some 3D printed PETG cups. Did I mention that there were 40 of them? For a maker, doing a thing once is kinda fun. Doing something 40 times becomes work! However, putting in the extra effort and doing something right usually works out in the end. hardy plants that do well in our Sonoran Desert. I’ll post another entry as I get closer to the actual event. Should be a great one this year!

hardy plants that do well in our Sonoran Desert. I’ll post another entry as I get closer to the actual event. Should be a great one this year!

Yesterday, I put up a couple of posts about our personality robots. I’ve always loved the idea of having robots. I remember asking Santa for a

Yesterday, I put up a couple of posts about our personality robots. I’ve always loved the idea of having robots. I remember asking Santa for a  Also, during the pandemic, I fulfilled another dream of mine. That was the desire to have a 3D printer for my workshop. COVID 19 restrictions gave me the luxury of being able to spend time learning about how to take rolls of plastic filament and turn

Also, during the pandemic, I fulfilled another dream of mine. That was the desire to have a 3D printer for my workshop. COVID 19 restrictions gave me the luxury of being able to spend time learning about how to take rolls of plastic filament and turn  them into useful and not so useful things around

them into useful and not so useful things around  the workshop

the workshop  and the house.

and the house.

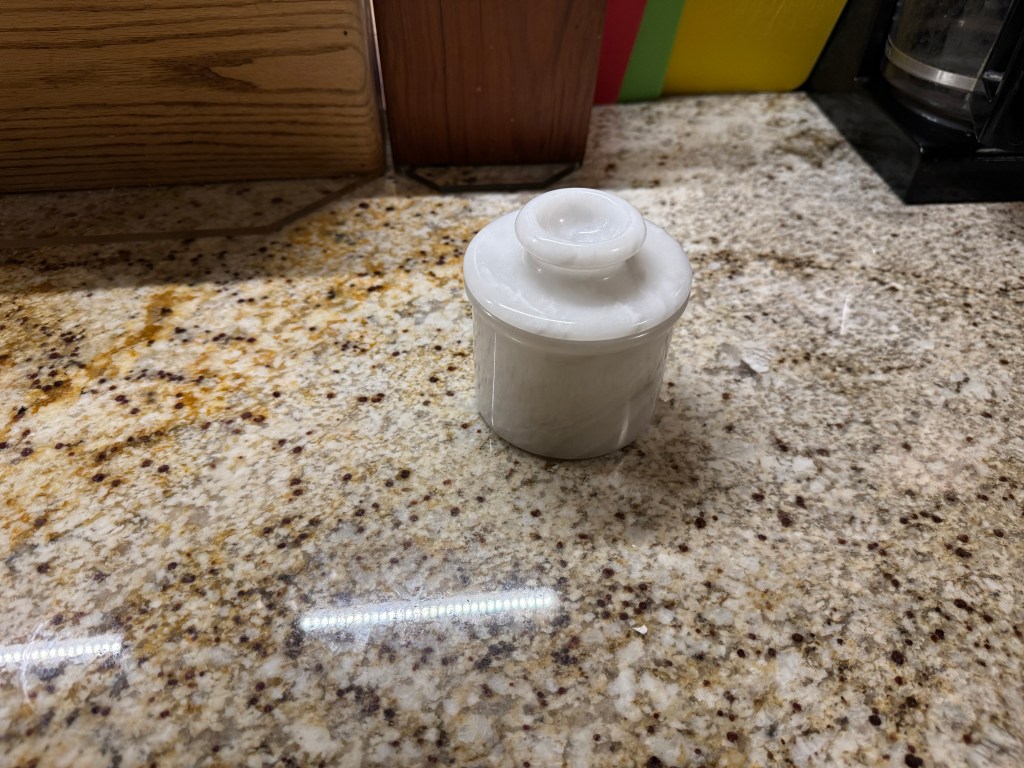

is beauty in having the machine, material, and experience to make your life a little bit better. Often, I’m up late at night on the computer and I need to put on a headset so I can hear the YouTube videos without disturbing Nancy. I always kept it in a drawer. I needed a way to avoid getting the set out a drawer, untangling the cord, and plugging it in to the USB port on the front of the tower. I decided to make a custom device that would attach to the tower.

is beauty in having the machine, material, and experience to make your life a little bit better. Often, I’m up late at night on the computer and I need to put on a headset so I can hear the YouTube videos without disturbing Nancy. I always kept it in a drawer. I needed a way to avoid getting the set out a drawer, untangling the cord, and plugging it in to the USB port on the front of the tower. I decided to make a custom device that would attach to the tower.

Happy New Year! However, the Chinese curse is still with us. Not talking about COVID 19, although that IS still with us. I’m talking about the curse that goes, “May you live in interesting times.” I’m going to try and make the best of 2024. One of the toughest things for me to do is throw things out. My favorite activity is making things. It’s particularly rewarding when I can improve on things that I already own or, better yet, use materials that I find. Throwing things out represents a failure to me. Unlike Marie Kondo, I get no pleasure out of discarding stuff. Particularly, if I remember how much money I paid for the stuff and I have a good memory. I often tell people that I’m a cardboard box short of being a hoarder. But things wear out and if they can’t be salvaged for parts, they must go. I’m beginning to believe that about relationships too.

Happy New Year! However, the Chinese curse is still with us. Not talking about COVID 19, although that IS still with us. I’m talking about the curse that goes, “May you live in interesting times.” I’m going to try and make the best of 2024. One of the toughest things for me to do is throw things out. My favorite activity is making things. It’s particularly rewarding when I can improve on things that I already own or, better yet, use materials that I find. Throwing things out represents a failure to me. Unlike Marie Kondo, I get no pleasure out of discarding stuff. Particularly, if I remember how much money I paid for the stuff and I have a good memory. I often tell people that I’m a cardboard box short of being a hoarder. But things wear out and if they can’t be salvaged for parts, they must go. I’m beginning to believe that about relationships too. Sunday was the last day of 2023. Nancy and I don’t go out on New Years Eve. This year we had some friends over to sing Karaoke and keep us awake until midnight. This was new for us, and we realized that we’d not have a big crowd because there were quite a few celebrations and many of our friends are a bit more active than we are. We had seven people join in and it was a good time. There were plenty of opportunities to sing before midnight. Earlier in the day, I used my remote fire making skills to wire up

Sunday was the last day of 2023. Nancy and I don’t go out on New Years Eve. This year we had some friends over to sing Karaoke and keep us awake until midnight. This was new for us, and we realized that we’d not have a big crowd because there were quite a few celebrations and many of our friends are a bit more active than we are. We had seven people join in and it was a good time. There were plenty of opportunities to sing before midnight. Earlier in the day, I used my remote fire making skills to wire up  a fire basket full of fireworks. We had champaign and sparkling cider, noise makers, and handheld sparklers to welcome in the New Year. The weather was “Tucson mild.” A light jacket was all that we required.

a fire basket full of fireworks. We had champaign and sparkling cider, noise makers, and handheld sparklers to welcome in the New Year. The weather was “Tucson mild.” A light jacket was all that we required. A few minutes of “oohing” and “aahing” and drinking and we were back in front of the Karaoke machine. The songs were varied: A Country song, followed by a show toon. There were folk songs and plenty of oldies. Everyone got a chance to sing eight songs if they wanted.

A few minutes of “oohing” and “aahing” and drinking and we were back in front of the Karaoke machine. The songs were varied: A Country song, followed by a show toon. There were folk songs and plenty of oldies. Everyone got a chance to sing eight songs if they wanted.

I added a cut-down Fiskars self-healing mat. I replaced the side runners on all the drawers so that they would pull out enough to reach the items in the back of them. I added shelving and lighting above the bench along with a power panel. I also added a “long bar” power strip along the front to support any corded hand tools. The last thing that I added was a way to mount a bench vice without ruining the surface of the bench for woodworking projects.

I added a cut-down Fiskars self-healing mat. I replaced the side runners on all the drawers so that they would pull out enough to reach the items in the back of them. I added shelving and lighting above the bench along with a power panel. I also added a “long bar” power strip along the front to support any corded hand tools. The last thing that I added was a way to mount a bench vice without ruining the surface of the bench for woodworking projects.